Maximized

Productivity

in Real-Time

The First Context-Aware Multi-Agent Factory OS

Connecting Workers, Machines and Processes on the Shopfloor for Optimizing Productivity

Increases Performance

of Workers and Teams

Transforms Every Worker

into an Agile Problem Solver

by Augmenting Their Capabilities with AI

Increases OEE of

Machines, Lines & Cells

Agents Continuously

Identify Optimal Production Parameters and

Maintenance Actions

Smart Decision-Making

Across All Operations

Unifies People, Assets

and Data in a Secure Way

for Factory Management

with Complete Information

Connected Agentic AI for Improving Production OEE

As digitalization accelerates across all industries, production plants must operate as well-orchestrated systems to stay competitive and profitable. This is exactly what Scopo Factory OS enables.

Our Operating System leverages smart devices to connect machine operators with specialized AI agents, receiving direct context about what is going on at the produciton line. Thus the AI continuously learns the best machine- and workflow parameter - per product, per raw material, and under any operating condition. This expert knowledge, gained by the AI, is then shared with all operators in real-time, establishing a consistent baseline of best practices that significantly improves your OEE.

Live Line 2

+18.4% OEE

Real-Time

Throughput

+12.7%

Downtime

- 31%

Scrap

- 9%

Because simply storing machine data is not enough. AI needs context to interpret what is happening on the shopfloor and to learn from it. That context comes from your staff—operators, supervisors, lab technicians, and your entire team.

Scopo Factory OS unifies all of this in a single architecture that is easy to deploy and fully compatible with your existing OT and IT systems. The result is a complete, secure, and integrated solution that keeps your production running at optimal parameters, with streamlined workflows and high-performing teams.

Adding 4 New Layers to Industry 4.0

MES / Factory Agent Layer

Production Line Agent Layer (Specialized AI)

Machine Agent Layer (Specialized AI)

SCADA, Unified Namespace, Brokers

Context Layer (Audio, Image, Video, Docs)

Communication Layer (Worker to AI, Speech)

PLCs, Gatewas, Protocols

Physical Machines

Our Products

Worker

Communication Modules

-

Scopo Smart Phone Apps

-

Multi-Modal Kiosks, located at machines

-

Headsets with microphone

-

Worker Onboarding-, Training- and Upskilling Apps

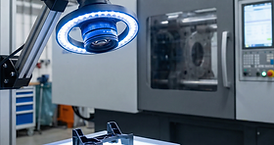

Inline QA

Integration Modules

-

AI-powered camera modules for part inspection

-

Temperature sensors

-

Humidity sensors

Laboratory

Integration Modules

-

Scopo Laboratory App

-

QR/Bar-Code Scanner for traceability

-

Connection modules for lab-equipment

Agentic

Machine AI

-

Specialized AI-Agents for each machine type

-

Fusing machine data with context from machine operators in real-time

-

Performs continuous analysis of each machine´s performance and finds measures how to improve OEE

Agentic

Production Line AI

-

Specialized AI-Agents for each production line-/ workcell-type

-

Fusing data from multiple machine agents with context from line operators, supervisors and laboratories in real-time

-

Performs continuous analysis of each line/cell´s performance and finds measures how to improve OEE

Factory Management

Modules

-

Machine Connection Middleware

-

AI-powered Dashboards

-

Agent-ready Historians

-

MES Connectors

-

ERP Connectors

-

Enterprise Reporting Modules

-

API / MCP for 3rd-Party AI Agents

Who is benefiting from Scopo Factory OS ?

Scopo Factory OS is built for labor-intensive industries that rely on highly trained human operators running complex machines under pressure. Whether your teams work across multiple shifts, must achieve high throughput with flawless quality, or face continuous upskilling demands, our Agentic Factory OS supports them end-to-end.

Ready for Various Production Types

01

Injection Molding & Press Operations of Plastics, Rubber & TPE

02

Extrusion of Plastics, Rubber & TPE

03

Metal Part Forming, Machining & Coating

04

Assembly of Technical Products in Workcells

In these Industries

Automotive

Medical Parts

Food Containers

Aerospace / Defense

Packaging

Construction

About Scopo

We are pioneering the next chapter of manufacturing by building an AI-based factory operating system that integrates people, machines, and data into self-optimizing cycles of productivity enhancements.

Scopo was born from the hard-won experience of deploying automation solutions across 800+ production lines in various industries and factories of all sizes. We didn't just install systems; we were there on the shop floor, and we saw when operators had no choice but to perform painstaking trial-and-error to find the new machine parameters and tool setups necessary to bring OEE back up after raw materials or conditions shifted.

We also found the factories constantly in a difficult situation: The skilled operator we had just trained on one machine would move to a different position a couple of months later. Factory processes ran sub-optimal until a new training slot for a new operator was found. Such cycle, often accelerated by the retirement of the most experienced workers, started all over again with every job shift.

What is Scopo?

SCOPO is the acronym for System for COlaborative Process Optimization. It was founded on the vision of a comprehensive factory operating system that enables industrial manufacturers - and everyone in the workforce - to conduct their processes more efficiently and at a higher level of effectiveness.

The Power of "Colaborative"

The emphasis here is on Colaborative: the fundamental belief that humans and AI must work together as a single team to reach new levels of performance and quality in manufacturing.

Operators bring in their essential expertise, observations, and opinions about the current situation. The AI instantly complements this by analyzing the situation alongside historical data from similar past conditions, external knowledge, and sophisticated predictions. The result is state-of-the-art support that ensures that operators are empowered to make the best decisions instantly.

This powerful teamwork digitizes the knowledge-sharing process, supporting your most experienced workers and making industrial careers highly attractive for new generations entering the workforce.